- Austenitic Stainless Steel ASTM A312/376 – 300 SERIES

- Ferritic/Austenitic Stainless Steel ASTM A790 – S31803 DUPLEX and S32750 SUPER DUPLEX

- Rollmet seamless pipe and tube is available in many other alloys such as zirconium, titanium, Alloy 200, 400, 600, 625, 718, 825, Alloy 20 and C276

- Specializing in large diameter thin wall pipe and tube

- 140 RA or better – I.D. finish

- Single random lengths – ASTM allowables

- Fine grain size for stainless grades runs 6 to 8 typical

- Wall tolerances better than ASTM allowables

- 50 years of manufacturing experience

- Minumum 35% cold work

- Cold Roll Extruded solid-solution alloy pipes offer greater strength than conventional manufactured pipe/tube because of the fine grain size achieved through cold working and recrystallization

- Cold Roll Extrusion, as a net process, achieves final pipe dimensions through metal displacement with very little waste

- Cold Roll Extrusion is performed at ambient room temperature

- Cold Roll Extrusion utilizes precision stainless steel and duplex starting blanks or extruded preforms as starting material for all stainless and duplex and super duplex production

- Isotropic properties can be achieved either as a cold worked tubular or in all finished annealed tubular products

- Enhanced corrosion resistance is achieved through ASTM 5 or finer grain size

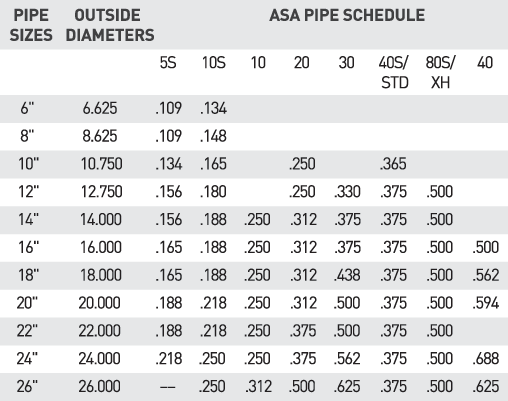

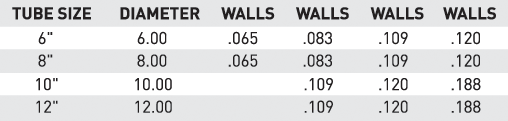

* Most diameter and light wall combinations of seamless tubes can be manufactured by PCC Rollmet, Inc.

- AS9100/ISO9001

- ISO 9001 approved

- AD2000-Merkblatt W0 approved

* Wall sizes available up to 1.5” on certain pipe sizes