- Ferritic Alloy Steel ASTM/ASME A335 – P5, P9, P11, P22, P91, P92, 125 to 150 RMS ID finish

- 15 to 24 ft single random lengths

- ASTM +/- 1% ovality tolerance met on all seamless pipes

- All seamless pipe within +10% /-5% of the nominal weight per ft for the entire length

- All seamless pipe within +/- 12.5% of the nominal wall call out per ASTM Specification

- Specializing in large diameter thin wall ferritic alloy steel pipe

- Cold Roll Extruded solid-solution alloy pipes offer greater strength than conventional manufactured pipe/tube because of the fine grain size achieved through cold working and recrystallization

- Cold Roll Extrusion, as a net process, achieves final pipe dimensions through metal displacement with very little waste

- Cold Roll Extrusion is performed at ambient room temperature

- Cold Roll Extrusion utilizes precision ferritic alloy starting blanks or extruded preforms as starting material for all ferritic alloy production

- Isotropic properties can be achieved in all finished annealed tubular products

- Enhanced corrosion resistance is achieved through ASTM 5 or finer grain size

- AS9100/ISO9001

- ISO 9001 approved

- AD2000-Merkblatt W0 approved

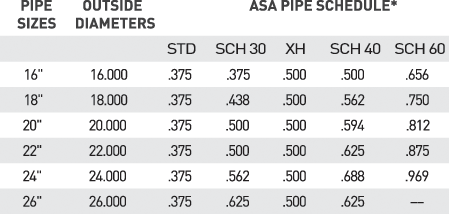

* Wall sizes available up to 1.5” on certain pipe sizes