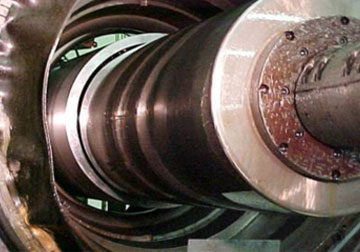

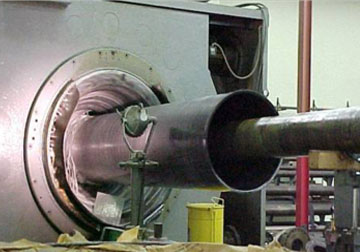

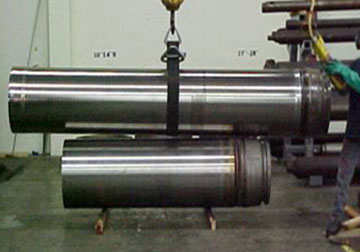

Cold Roll Extruded solid-solution alloy pipes offer greater strength than conventional manufactured pipe/tube because of the fine grain size achieved through cold working and recrystallization. As a net process, it achieves final pipe dimensions through metal displacement with very little waste.

- 50 year proven process

- Available in nickel, stainless steel, duplex and super duplex alloys and grades

- 5 or finer grain size achieved for enhanced corrosion existence per ASTM E 112

- 45% to 75% cold work applied to starting material to achieve higher mechanical properties

- 20% to 35% higher mechanical properties than ASTM-ASME minimum requirements

- Properties are isotropic circumferentially and along the entire length of finished seamless pipe

- 125-140 RA ID finish or better

- Polished OD surface

- Meets ASTM G28 A and B corrosion test requirements

- Meets ASTM G48 A and B corrosion test requirements

- Meets ASTM 262 practices A, B, C and F intergranular corrosion tests

- NACE MR0103 and NACE MR0175 compliant

- Cold roll extrusion is a 100% cold working process. It is not a hot extruded process with minimal straightening or sizing applied to the piping material to barely meet minimum cold worked mechanical properties required of the material specification.