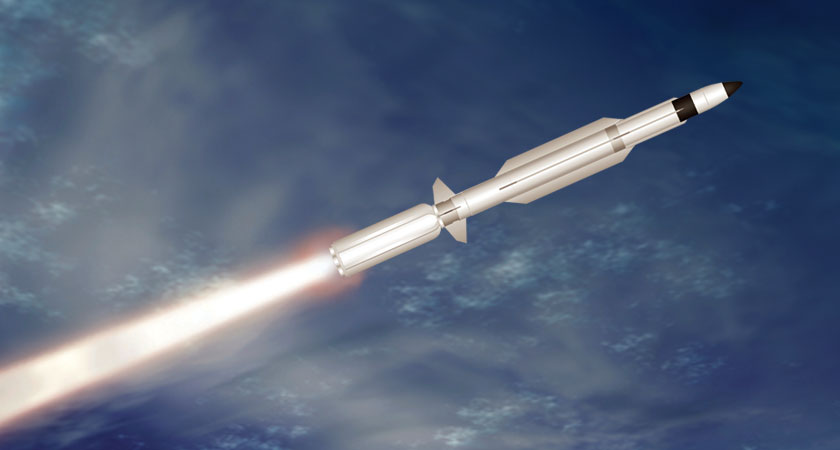

PCC Rollmet has been a leader in the development and manufacture of Defense and Missile related products since the 1960’s. Our years of experience combined with state-of-the-art capabilities enable us to transform raw materials to high level Defense/Missile assemblies.

- Missile launch tubes and assemblies

- Rocket motorcases

- Machined components and closure assemblies

- Pressure vessels and pressurant tank liners

- Nuclear submarine piping

- Propulsion tank assemblies

- Trainer shapes and assemblies

- Nozzle bodies

- Airframe components

- Raytheon Missile Systems

- Aerojet Rocketdyne

- General Dynamics

- The Boeing Company

- Huntington Ingalls – Newport News Shipbuilding

- Lockheed Martin

- U.S. Navy

- ATK

- AAR Corporation

- United Technologies

- Single source supplier for precision cylindrical welded assemblies

- Precision GTAW welding to 34 feet

- Close tolerance, thin-walled cylinders unattainable by machining are routinely Cold Roll Extruded in materials such as:

• Aluminum alloys, stainless steels, high strength steels, nickel-based alloys, and other high weight-to-strength ratio materials

- Ability to vary wall thicknesses resulting in:

• Localized thickened areas for attachment points and weld joints

• Thinner areas to maximize structural weight efficiency

- AS9100/ISO9001

- ISO 9001 approved

- AD2000-Merkblatt W0 approved